The Process

Blowmolding is the process of heating plastic pellets and converting them with air into a hollow finished part.

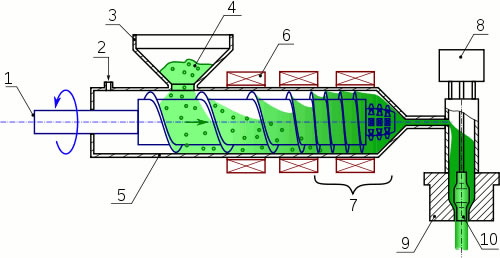

To start with, a metal screw, #1, turns inside an enclosure called a barrel, #2. Resting on top of this is a material mixing device, #3, which drops plastic pellets (#4) into the screw, which is located inside the barrel, #5. Heat is added via heater bands, #6, which turns the hard plastic pellets into a soft pliable state.

The plastic is then pushed through the head of the machine, #8, and through the head tooling, #9 to form what is referred to as the parison #10.

This parison is then captured by a set of water cooled molds and has air pressure introduced to force the parison to take the shape of the mold's cavity. Once cooled, the part is removed and trimmed.

Blowmolding offers:

• Low Tooling Cost

• Low Part Cost

• Lightweight, Strong Parts

• High Resistance to Corrosion

• Low to High Production Runs